E&T - Engineering and Tooling Group

We have focused the activity of our companies on engineering, development and manufacturing.

Renowned brands from the most diversified sectors and markets are our clients.

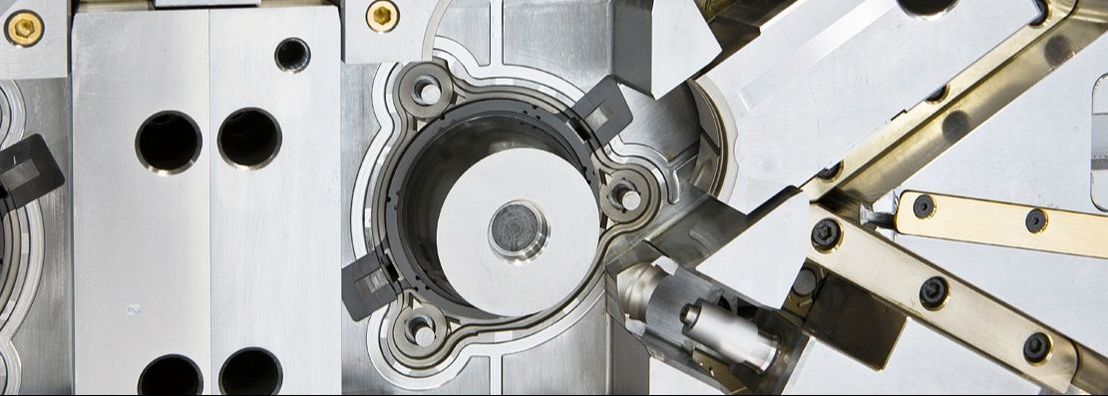

We export injection molds for the plastics industry.

Today, the E&T Group is the image of the experience acquired by many years of activity in the tooling industry.

Our consolidated experience is ever-increasing.

Through the resolution of the continuous challenges presented by technological development, as well as from market demands.

Some of our experience includes, but is not limited to

• multi-component molding, material or color, 2K or two-shot

• insert molding and overmolding (vertical, horizontal, index-plate, rotary platen or turntable and transfer molds)

• stack-molds

• in-mold labeling

• GAIM (Gas-Assisted Injection Molding)

• RHCM Variotherm (Rapid Heat Cycle Moulding, with water)

The staff encompasses specialized technicians for the most diverse areas.

All along with state-of-the-art technology.

It enables E&T to meet the client’s needs completely.

The Group is always looking for:

• the best quality

• the shortest deadlines

• the most competitive prices

Our foremost aim is client satisfaction.

Then we can develop a strong commercial relationship.

Based on a spirit of partnership and mutual trust.

Our main markets are automotive, electrical and electronics, medical and also consumer goods.

Turnkey project management (mold, automation, quality inspection or measuring devices) can be provided on demand.

Today, the E&T - Engineering and Tooling Group has an important place in the balance of exports in Portugal, within it's sector.

After approval of the project, E&T starts the manufacturing phase.

We plan the process and operations needed.

This way, the agreed deadlines are always met.

Our technical team, at E&T, supervises the entire project.

Right from the start, all the way to the delivery at your plant.

After-sales support is also included with all projects.

Periodic reports of the work in progress, along with digital photos, are both sent to the client.

We also provide customer access to web-based progress reports and project monitoring.

We document all operations with technical reports, adequate for the serial production phase.

We have focused the activity of our companies on engineering, development and manufacturing.

Renowned brands from the most diversified sectors and markets are our clients.

We export injection molds for the plastics industry.

Today, the E&T Group is the image of the experience acquired by many years of activity in the tooling industry.

Our consolidated experience is ever-increasing.

Through the resolution of the continuous challenges presented by technological development, as well as from market demands.

Some of our experience includes, but is not limited to

• multi-component molding, material or color, 2K or two-shot

• insert molding and overmolding (vertical, horizontal, index-plate, rotary platen or turntable and transfer molds)

• stack-molds

• in-mold labeling

• GAIM (Gas-Assisted Injection Molding)

• RHCM Variotherm (Rapid Heat Cycle Moulding, with water)

The staff encompasses specialized technicians for the most diverse areas.

All along with state-of-the-art technology.

It enables E&T to meet the client’s needs completely.

The Group is always looking for:

• the best quality

• the shortest deadlines

• the most competitive prices

Our foremost aim is client satisfaction.

Then we can develop a strong commercial relationship.

Based on a spirit of partnership and mutual trust.

Our main markets are automotive, electrical and electronics, medical and also consumer goods.

Turnkey project management (mold, automation, quality inspection or measuring devices) can be provided on demand.

Today, the E&T - Engineering and Tooling Group has an important place in the balance of exports in Portugal, within it's sector.

After approval of the project, E&T starts the manufacturing phase.

We plan the process and operations needed.

This way, the agreed deadlines are always met.

Our technical team, at E&T, supervises the entire project.

Right from the start, all the way to the delivery at your plant.

After-sales support is also included with all projects.

Periodic reports of the work in progress, along with digital photos, are both sent to the client.

We also provide customer access to web-based progress reports and project monitoring.

We document all operations with technical reports, adequate for the serial production phase.

AFR Moldes, founded in 1999, is the manufacturing unit of the E&T Group.

It has since increased its manufacturing capacity and level of specialization.

Today it owns a manufacturing area of about 14.000 sq. ft. (1300 m2).

On the shop floor, there are 40 specialized technicians, running the machine park.

The machines are quite up-to-date.

Demands from the industry, drive the investments.

But also the innovative and entrepreneurial spirit of the company’s board.

AFR Moldes invests in state-of-the-art technology.

We also invest in specialized training.

This provides the skills needed to manufacture any kind of injection mold, weighing up to 22.000 lb.

All in all, the company now stands out as one of the most well equipped within its sector.

Both stand out, the specialized workforce and the technology.

It has since increased its manufacturing capacity and level of specialization.

Today it owns a manufacturing area of about 14.000 sq. ft. (1300 m2).

On the shop floor, there are 40 specialized technicians, running the machine park.

The machines are quite up-to-date.

Demands from the industry, drive the investments.

But also the innovative and entrepreneurial spirit of the company’s board.

AFR Moldes invests in state-of-the-art technology.

We also invest in specialized training.

This provides the skills needed to manufacture any kind of injection mold, weighing up to 22.000 lb.

All in all, the company now stands out as one of the most well equipped within its sector.

Both stand out, the specialized workforce and the technology.

KNOW-HOW

Throughout its existence, AFR Moldes gathered knowledge and skills.

We executed a diversity of projects, more than 800 tools over the years.

It allowed us to apply the most adequate engineering solutions and processes.

This ensures the highest quality and functionality of all its elements.

Besides AFR Moldes, E&T also relies on a structured network of about 10 local tool shops.

This network capacitates the Group to manage several large projects at once.

This concept provides a solution to the customer as if it were a single supplier.

Supported by its internal organization, large projects progress with ease and speed.

All without extra costs or responsibilities for the client.

We design solutions according to the client’s demands, with the purpose of

- providing manufacturing quality

- ensuring reproducibility of the process

- all with easy maintenance

Throughout its existence, AFR Moldes gathered knowledge and skills.

We executed a diversity of projects, more than 800 tools over the years.

It allowed us to apply the most adequate engineering solutions and processes.

This ensures the highest quality and functionality of all its elements.

Besides AFR Moldes, E&T also relies on a structured network of about 10 local tool shops.

This network capacitates the Group to manage several large projects at once.

This concept provides a solution to the customer as if it were a single supplier.

Supported by its internal organization, large projects progress with ease and speed.

All without extra costs or responsibilities for the client.

We design solutions according to the client’s demands, with the purpose of

- providing manufacturing quality

- ensuring reproducibility of the process

- all with easy maintenance

In 2015, E&T opened a new center of mold testing and pre-series production.

This new center, E&T Plastics, comprehends four ENGEL injection machines.

The clamping forces are 160, 300, 500 and 800 tons.

There is a clean shop floor with a modern underground feeding and material drying system.

All are equipped with a robot and a conveyor belt.

So it is very convenient to collect and pack the parts.

We can run two-shot overmolded parts (2K) with our mobile injection unit.

We also have a rotary table.

For transfer tools, we can provide the EOAT / grippers.

CMM

As a way to ensure the final quality of the product, a new metrology lab was also created.

Equipped with a modern multi-sensor coordinate measuring machine from Werth.

This new center, E&T Plastics, comprehends four ENGEL injection machines.

The clamping forces are 160, 300, 500 and 800 tons.

There is a clean shop floor with a modern underground feeding and material drying system.

All are equipped with a robot and a conveyor belt.

So it is very convenient to collect and pack the parts.

We can run two-shot overmolded parts (2K) with our mobile injection unit.

We also have a rotary table.

For transfer tools, we can provide the EOAT / grippers.

CMM

As a way to ensure the final quality of the product, a new metrology lab was also created.

Equipped with a modern multi-sensor coordinate measuring machine from Werth.